Machine park EDM -spark erosion center

At Nefratech EDM-Center, the latest machines are ready for you!

Within Europe, we, as Nefratech EDM-Center have a unique machine park. And we are proud of it. We develop our machine park in anticipation of the demand from the market. Als EDM professionals we like to be the first when it comes to the latest technological challenges in the area of spark erosion! That is why we keep investing continuously in our machine park and also in people.

Nefratech EDM-Center, for instance, has been offering, ever since 2000 – and as one of the first – the 5-axle simultaneous wire EDM.

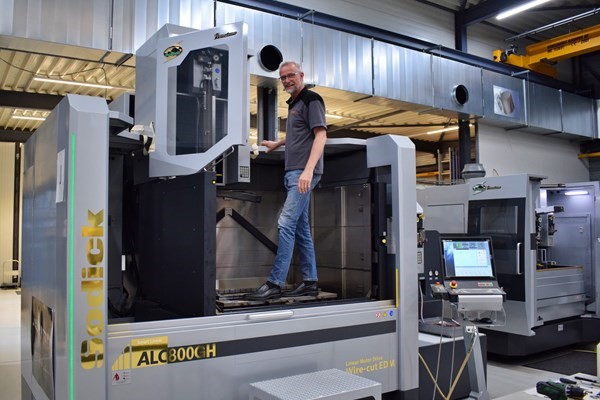

As from 2019, we are even the only Dutch producer able to handle large and heavy workpieces up to 3,000 kilos with high accuracy. The Sodick ALC 800GH is our showpiece!

But in addition to implementing complete productions, we at ‘Nefratechers’ also offer the execution of specific division operations. Do you have a specific question, feel free to ask us for advice. We will be happy to share our insight and experience with you!

8-axle (prepared) simultaneously wire EDM

Not only is Nefratech EDM-Center unique because of the 5-axle simultaneous EDM, but also because we are 8-axle prepared!

In Europa, we, as a company are even the only party that is ready for the realisation of an 8-axle simultaneously produced spark product! This option is offered in consultation, as soon as this is required by your product.

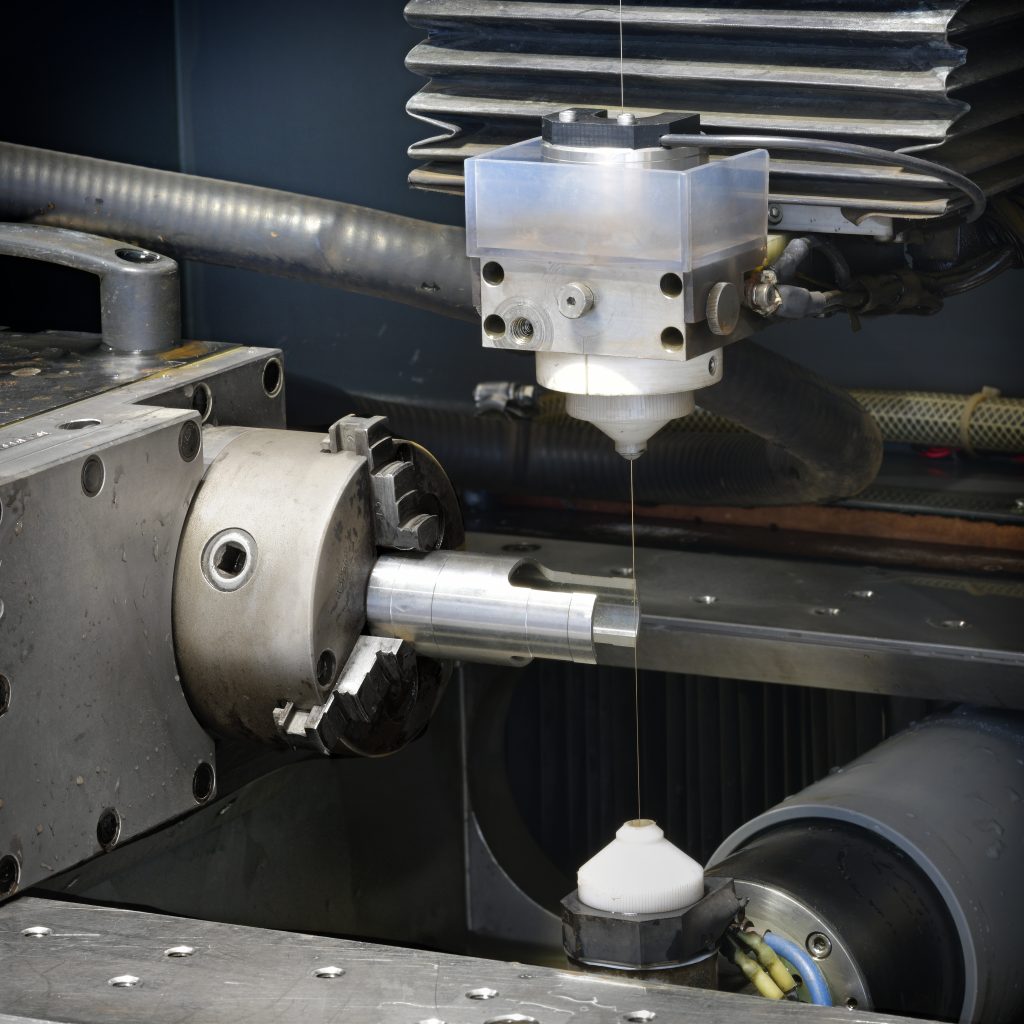

Precision processing

Every fine mechanical part is manufactured in accordance with the drawing or based on a 3D-model. Drawings are discussed externally and/or internally beforehand, before the team starts working on them. Nefratech EDM-Center even specialised in precision processing with tolerances to 0.002 millimetres; these tolerances are measures accurately.

Wire EDM, EDM machining and start hole EDM drilling is taking place in-house, in the own workshop. For CNC-milling – in combination with EDM – and for specific editing, we collaborate with renowned partner businesses. We can support the entire process on behalf of you.

Also read: What is cheaper, machining or milling?

Or: when do you choose machining or milling?

Wire EDM machines

CNC-spark drilling machines

Max. size of the workpiece

1,250 mm x 1,000 mm with a reach of 800 x 600 x 800 mm in height

Surface roughness

0,3 μRa

Table load

maximally 3,000 kg

Read the article on www.fpt-vimag.nl of 16 July 2019 about the commissioning of this machine.

FANUC ROBOCUT Alfa 0-C wire EDM specialist

Max. size of the workpiece

600 mm- 300 mm – 180 mm

Max. workpiece scope

320 mm – 220 mm – 180 mm

Table load

400 kg

FANUC ROBOCUT Alfa 0-iA wire EDM specialist

Max. size of the workpiece

600 mm- 300 mm – 180 mm

Max. workpiece scope

320 mm – 220 mm – 180 mm

Table load

400 kg

SODICK AQ750LH wire EDM specialist

Max. size of the workpiece

1050 mm – 750 mm – 600 mm

Max. workpiece scope

750 mm – 500 mm – 600 mm

Table load

3000 kg

FANUC ROBOCUT Alfa 1-C wire EDM specialist

Max. size of the workpiece

790 mm – 730 mm – 300 mm

Max. workpiece scope

520 mm – 370 mm – 300 mm

Table load

1000 kg

FANUC ROBOCUT Alfa – 1iA draadvonker

Max. size of the workpiece

790 mm – 730 mm – 300 mm

Max. workpiece scope

520 mm – 370 mm – 300 mm

Table load

1000 kg

EDM machine

CNC-EDM drilling

CNC starter hole spark drilling machine MADRA BT-2CNC

Max. workpiece scope

350 mm – 250 mm 350 mm

Max. size of the workpiece

600 mm – 300 mm – 350 mm

Table load

200 kg

Starter hole spark drilling machine MATRA BT-2

Max. workpiece scope

350 mm – 250 mm 350 mm

Max. size of the workpiece

600 mm – 300 mm – 350 mm

Table load

200 kg